How to Plan Dielines for Packaging

When choosing product packaging, you want to make sure you fully understand how its design will benefit your product. That’s where packaging dieline comes in.

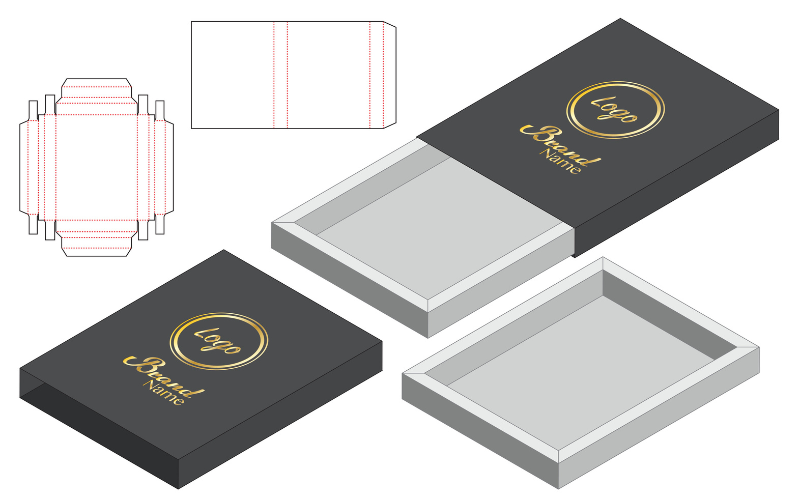

Dielines for packaging are a blueprint that dictates how your final packaging product will be printed and arranged. It shows you where graphics should be placed for optimum visibility and helps ensure the design is consistent, visually appealing, protective, and producible.

Learning how to plan packaging structure—and what to look for in a packaging design company—will save you significant time and money down the road.

What are Dielines in Packaging?

A dieline is a digital template used in the design and production of packaging materials, such as boxes, bags, or cartons. Dielines are premade outlines that show where packaging should be creased, cut, and glued to create a specific shape and size.

Dielines are typically created using specialized software like Adobe Illustrator or ArtiosCAD. They are usually provided by the packaging manufacturer or printer. Dieline designs can be customized to meet the specific requirements of a given product and are an essential tool for ensuring the packaging is produced accurately and consistently.

Packaging designers and engineers use dieline packaging designs to create mock-ups or prototypes of the packaging, test the fit and functionality of the design, and make any necessary adjustments before final production.

Overall, dielines are critical to the packaging production process, helping to ensure that packaging materials are efficient, effective, and meet the needs of both the product, market, transportation and the consumer.

How to Plan Dieline Packaging Designs

If you work with a packaging engineer and designer, you won’t have to worry about this yourself. However, it can be helpful to understand the process. Planning dieline packaging designs involves many steps:

- Gather information: The first step is to gather all the necessary information about the product that will be packaged, such as its size, shape, weight, and fragility. You will also need to consider any regulatory requirements or industry standards that may apply to the packaging.

- Determine the packaging type: Next, you need to decide on the type of packaging that will be used. This could include options such as a printed box, bag, carton, or label.

- Create a design concept: Once you have determined the packaging type, you can create a design concept that meets the requirements of the product and any other relevant factors. This may involve creating sketches or mockups of the packaging design.

- Create the dieline: Using specialized software like Adobe Illustrator or ArtiosCAD, you can create the dieline for the packaging design. This involves creating a flat pattern template that shows where the packaging should be folded, cut, and glued to create the desired shape and size.

- Test and refine: Once you have created the dieline, you can use it to create a prototype of the packaging design. This will allow you to test the fit and functionality of the design and make any necessary adjustments before final production.

- Finalize the design: Once you are satisfied with the packaging structure, you can proceed with creation of final graphics.

Qualified packaging professionals should pay careful attention to detail, have extensive knowledge of a product’s packaging requirements, and understand industry-specific requirements.

Related Content: What is a Packaging Engineer and Why Your Brand Needs One

Who Usually Plans Dieline Packaging Designs?

In a packaging company, the planning of dieline packaging designs is typically the responsibility of packaging designers and engineers. These professionals are trained in the design and production of packaging materials, and they use specialized software and equipment to create dielines and other packaging design elements.

Packaging designers are responsible for creating the overall concept and visual design of the packaging, while engineers focus on the technical aspects of the design, such as the materials, production process, and structural integrity of the packaging.

The specific roles and responsibilities of packaging designers and engineers may vary depending on the company and the nature of the packaging project. In some cases, a single individual may be responsible for both the design and engineering aspects of the project, while in larger companies, there may be separate teams for each function.

Takeaway

Ideally, your packaging company will have both packaging designers and engineers on-site, as this greatly speeds up turnaround time and makes for a more efficient process. The planning of dieline packaging designs requires specialized knowledge and expertise in packaging design and engineering, as well as a thorough understanding of the product and the requirements of the customer and consumer.

The dieline truly is the foundation of well-designed packaging and the template from which your final product will blossom. Don’t skip any steps, and choose the right packaging partner for the job.