Uses of Embossed and Debossed Design Elements in Product Packaging

Uses of Embossed and Debossed Design Elements in Product Packaging

Remember begging your mom for those lunch boxes with super heroes or cartoon characters on them when you were a kid?

My favorite was Spider Man. I distinctly remember the picture of him socking some bad guy in the jaw, his rock hard muscles raising like blisters from the metal cover of the box.

That’s a printing technique called embossing, which originated with hot stamping personalized stationary in the Fifteenth Century. This design technique is still used in package printing today. You can add embossing or debossing to your product packaging design and incorporate it into your marketing strategy, and the options aren’t limited to paper.

Embossing and debossing your printing surface enhances the packaging’s appearance in strategic ways. We explain the difference between the two techniques, and when you should think about using them in your design.

Embossed Printing for Product Packaging

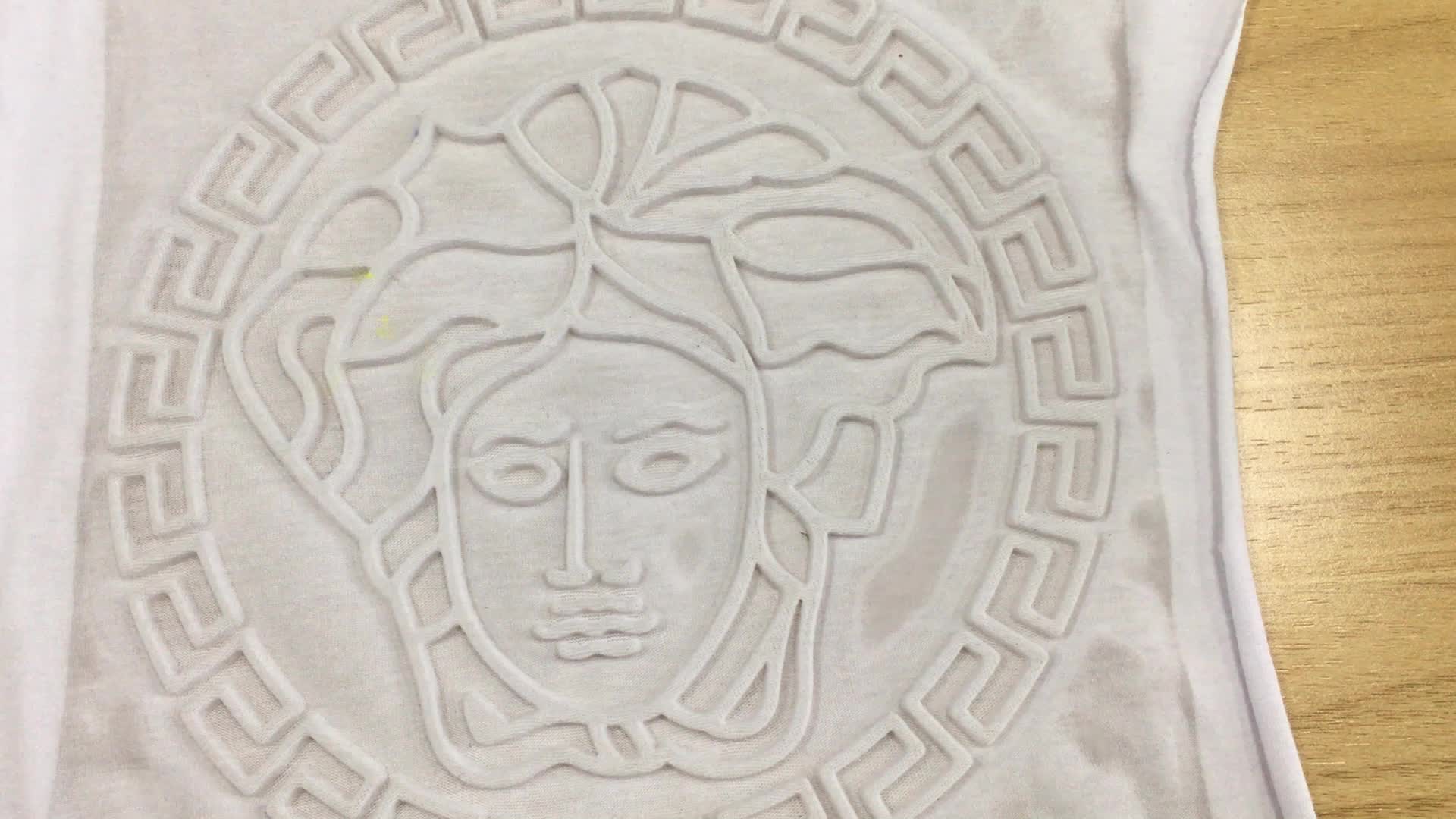

When it comes to product packaging print solutions, embossed stamping has a raised surface. When paper or plastic is embossed, the embossed portion will rise up from the substrate material.

Embossing allows you to use various enhancements and lends itself to sculpturing your package designs. With sculptured embossments, you can achieve a detailed finish. For example, say you’re printing packaging for a set of kids’ Hulk figurines. Sculpting and embossment would allow you to pop the Hulk’s muscles right out from the packaging surface and make them glimmer in certain lights and from different angles. When the buyer runs their fingers over the packaging surface, they’ll feel the outline of the embossed area. This gives product packaging more of a 3D look.

Embossing can accentuate high-impact graphics in your packaging design in other cases as well. When a graphic image needs to stand out, like your logo for example, embossing those aspects of the design will help draw the consumer’s eye.

Matte laminate and UV gloss varnish can also be applied to the embossed part so that it pops from the packaging. When you see these enhancements on the shelf in a store, it appears more eye-catching because the surface isn’t catches the light differently. An overall matte finish offsetting areas of spot UV varnish will enhance the appearance even more.

This design technique is often used for packaging for items like collectibles, cosmetics, gaming products, and special editions.

Debossed Printing

Debossed stamping is inverted in the print process, and yields a look that’s a little more understated than embossing. It is stamped from the outside of the paper and will recede from view when you’re looking at the paper from the outside.

Debossing is used less often than embossing, and is typically reserved for items like stationary. Seals with an official-looking appearance, certifications, and ribbon graphics are also traditionally debossed, with the seal being pressed down into the paper.

Combining Embossing and Debossing

You don’t have to pick one or the other. In fact, using embossing and debossing in the same design can enhance the overall effect, giving more packaging greater depth while drawing attention to specific elements.

If you’re selling road race games, for example, and you want your packaging to feature a race car that’s sculptured and pops out of the packaging a bit, while the potholes it’s zooming over are recessed into the packaging and appear black in color, you can do that with a design that combines embossing and debossing.

Online vs. Retail Shops

Though embossing and debossing both have a more immediate visual impact on the buyer’s impression of goods sold in retail stores, online shoppers often give more favorable reviews when the item comes in impressive packaging. People leave comments on the quality of the packaging for goods bought online, and positive comments help encourage future sales.

A good photographer with proper lighting equipment should be able to capture the visual appeal of an embossed or debossed design and optimize the image for online retail.

What You Need to Know Before You Order

Both embossed and debossed printing require certain metal plate guides, and there are risks of damaging your packaging if they are not done correctly.

An experienced designer will know how to incorporate the feature and avoid the hazards of getting too close to a score or cut on a box. They can create a quality design that will use the appropriate sloping to ensure there’s no danger of tearing in the die cutting phase or distressing the paper too much.

Your packaging printer can help you with design and everything you’ll need, including advising you on the quantities and volumes that justify the cost of using embossing and debossing.

Added costs associated with embossing or debossing will vary. Sometimes, the cost may be negligible. The size of the packaging will factor into the cost, as will your order volume and the complexity of the die.

When you’re planning your packaging design, consider which elements could be highlighted or made more appealing with an embossed or debossed element or two. These enhancements sometimes make all the difference between a product that blends in with others on the shelf and one that grabs the consumer’s attention. It makes the package more fun to look at and touch, and once it’s in the buyer’s hands, you’ve won half the battle of getting it to the checkout.