Big Box Considerations

You might think packaging requirements are consistent from store to store—but they actually vary widely.

While each big box retailer outlines specific guidelines around branding, transportation, weight, pricing, sustainability, and how products fit into their unique store environment, there are some general guidelines that can help inform your pitch.

.jpg?width=4032&height=3024&name=franki-chamaki-ZLaxv6iiLcI-unsplash%20(1).jpg)

Sample Packages

Packaging requirements often include:

1. Barcode and labeling requirements, such as the inclusion of a UPC code and specific product information.

2. Durable packaging that can withstand shipping and handling.

3. Eco-friendly packaging options, such as recyclable materials.

4. Consistent packaging, to ensure a uniform appearance on the shelves.

Specifics for each major retailer drill down into guidelines on PDQ packaging measurements, pallet display particulars, and eco-friendly material practices, among many other requirements. Since these requirements differ, it’s important to understand each and design your packaging accordingly.

Going into your pitch fully prepared with the right packaging could make or break the outcome. With all big box retailers, one surefire way to succeed in any sales pitch is to incorporate Retail Ready Packaging.

What is Retail Ready Packaging?

Retail Ready Packaging (RRP) is packaging designed specifically for display on retail store shelves.

RRP often refers to boxes in a tray or other packaging types that can be easily stocked. Big box retailers look for this type of packaging and often require it as they prioritize speed-to-shelf. Walmart, for example, measures the seconds it takes to stock a product on the shelf. This consideration is important given the volume of products big box retailers work with.

Retail Ready Packaging must also be durable, attractive, and should clearly display the product and its information. RRP often includes features such as perforated or easy-open packaging, hanger holes, header cards, or display boxes.

Big box retailers have their own specific guidelines and requirements when it comes to retail ready packaging, so you’ll want to make sure you know what those are as you’re preparing your

pitch.

Retail Sales Pitch Preparation

Unfortunately, retailers often don’t make their specifications available online, and requirements change. Partnering with an experienced packaging supplier who knows the ins and outs of working with big box stores will increase your chances of success.

You’ll also want to make sure you know your numbers, such as costs for packaging and display, fulfillment costs, accounting for returns, and other details about your products and packaging.

Read on to learn packaging guidelines for Walmart, Costco, Home Depot, and BJ’s.

Short on time? Download your own copy of the guide.

Considerations for Walmart

Walmart is the largest brick-and-mortar retailer in the United States. If you want to find your product on its shelves, you need to understand its seller rules and regulations before scheduling

a sales presentation.

To successfully pitch your products to Walmart, keep the following in mind:

- Clarity and simplicity: Walmart requires packaging to be easily legible, with a focus on the product and its benefits. The packaging should be easy to understand, even for customers who may have limited English skills.

- Compliance with regulations: Like all retail stores, Walmart requires packaging to comply with relevant federal and state regulations, including those related to labeling, safety, and the environment.

- Supply chain efficiency: Walmart is focused on improving logistics throughout the supply chain, and they expect their suppliers to do the same. This includes using efficient packaging designs and materials that minimize waste and reduce handling time.

- Walmart has established sustainability goals and aims to reduce waste and promote environmentally responsible packaging.

- The company’s “Packaging Scorecard” evaluates products based on factors such as recyclability, materials used, and energy efficiency.

- Walmart encourages vendors to use smaller, lighter, and more compact packaging to reduce shipping costs and minimize waste.

- Packaging should be appealing, easily recognizable, and protect the product during transportation and display.

Retail Fixtures Overview

Not all Walmart fixtures are identical, but the vast majority include five primary elements. The side counter shelves will hold the vast majority of merchandise, while the aisle shelf at the base is good for bulkier products. Most shelves feature an end cap, which sits on the side of the display and usually features specialty or seasonal merchandise.

Sidekick wire frames are an optional addition that may or may not be affixed to the side counter shelves or end cap. Use these wire frames to hold lightweight or temporary displays. Finally, Walmart’s signature price holder signs indicate the best deals and highlighted products on the endcap.

PDQ Display Rules

Pretty darn quick or “PDQ” displays are great temporary displays, especially if Walmart is showcasing your products for a trial period. Before signing a contract with them, you need to understand four simple rules about PDQ displays.

- Message Clarity

The first rule is “Deliver the Message.” Make sure the price is clearly displayed, and use the principles of functional retail design to show the value of your products. In a nutshell, your PDQ displays need to create a welcoming in-store experience for customers that will encourage them to make purchases. That includes making sure all claims on your packaging are verifiable. - Display Integrity

The second rule of PDQ packaging is “Display Integrity —using materials with proven structural integrity so you can avoid making a poor impression with damaged merchandise. Walmart will only accept corrugated cardboard produced from ECT32 boards or stronger. Don’t use E or F flute corrugated cardboard and test the material to ensure it meets strength requirements.

- Goal Post Price Signs

Walmart’s third rule involves “Goal Post Price Signs,” which are available in-store and inserted into product packaging to clearly display the price of the product. Your PDQ packaging must hold these goal post price signs safely and securely. Standard solutions include pop-out corrugated brackets, holes through the center of the display, and triangle holes in the back corner of trays. In addition to accommodating the signs, the holes must read “Insert Goal Post Here” for store associates to know where to place the sign.

- Product Turn

Only deliver as much inventory as Walmart can realistically sell before your next shipment. If your merchandise sells too quickly, you’ll both take a hit with wasted shelf space. If your products don’t sell well enough, you’ll have excess inventory and nowhere to store it. Always use internal metrics to gauge inventory turnover before agreeing to a contract with Walmart.

Pallet Displays

Because they use inexpensive materials, pallet displays provide a cost-effective means to sell large volumes of merchandise at Walmart.

In terms of volume, pallet displays should maximize the amount of merchandise within the space, while leaving 15 percent air space at the center of the unit. They should be filled from the floor to the height of the display unit.

Don’t include false bottoms or any display with more than 50 percent air space, as these displays will waste valuable floor space. Make sure that your merchandise actually fits the footprint of the pallet within one inch of the edge

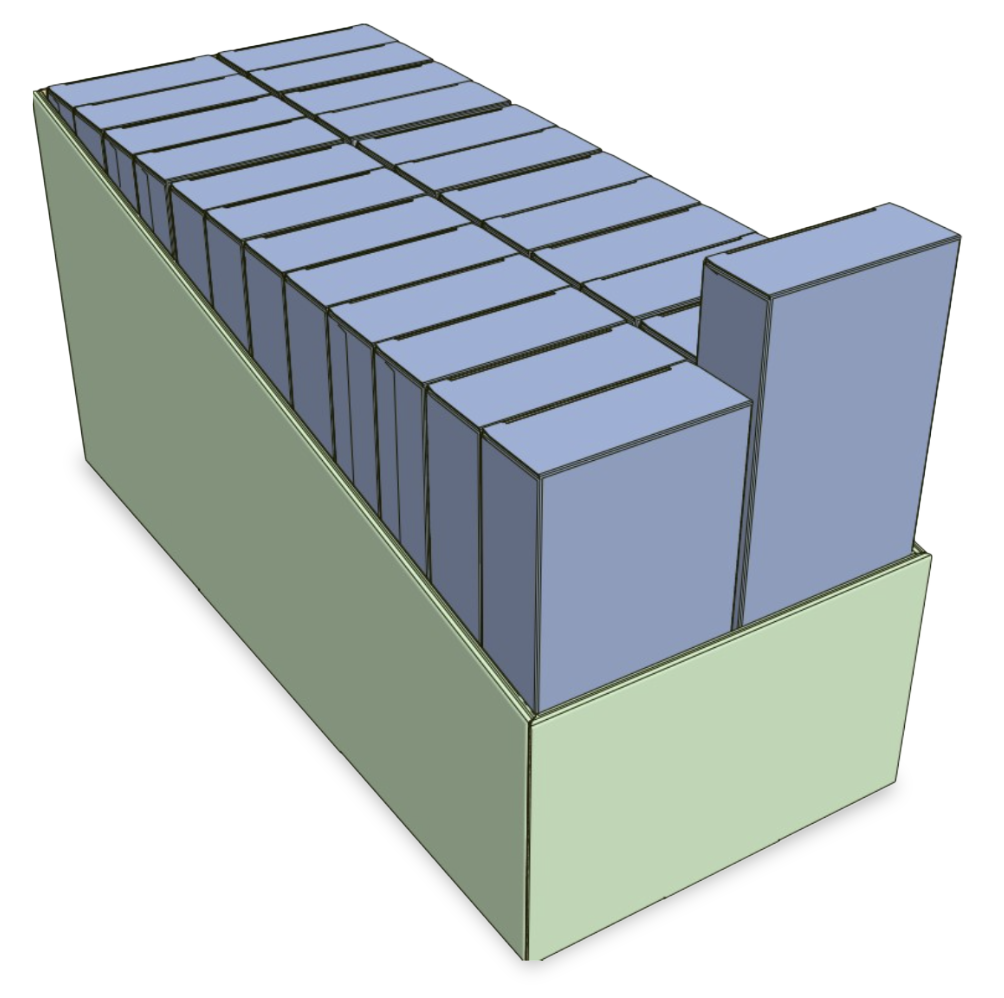

PDQ Trays

PDQ trays can seamlessly integrate your brand into an existing shelf at Walmart.

They should be easy to restock for associates without sustaining any damage to the packaging. Your products should be safely contained with the PDQ tray and provide easy access for customers.

PDQ trays should be ½ inch shorter than the total length of the shelf. Walmart only allows PDQ

trays that weigh less than 50 pounds.

The front lip of your PDQ tray must be no shorter than two inches and should be higher if you sell heavier merchandise in order to guarantee stability. Walmart recommends rollover lips, which increase sturdiness and reduce the possibility of paper cuts.

If you use a high-back or stadium tray, ensure the back is at least as tall as the top of your product. Here is a typical PDQ structure that does not require glue for the setup.

Considerations for Costco

With nearly 850 locations worldwide, Costco provides an incredible opportunity to showcase your products. Compared to other retailers, Costco places more focus on “bulk” and “club-pack” sizes, which allows them to offer larger quantities of items at a lower price.

Here are several Costco specific guidelines to keep in mind as you prepare your pitch:

- Sustainability:

Costco places emphasis on sustainability packaging that reduces waste, saves space, and makes efficient use of materials. Consider using recycled or recyclable paper products, biodegradable plastics, or reducing the weight of your packaging to save fuel during shipping. - Cost effectiveness:

Costco prioritizes cost effectiveness, and they expect their suppliers to do the same. This includes using packaging that is both functional and cost-efficient. - Clarity and simplicity:

Costco requires packaging to be clear and simple, with a focus on the product and its benefits. The packaging should be easy to understand and free of visual clutter. - Compliance with regulations:

Costco requires all packaging to comply with relevant federal and state regulations, including those related to labeling, safety, and the

environment. - Ease of Use:

Packaging should be easy to open, clearly labeled, and protected from damage during shipping.

Sample Packages

Costco places heavy emphasis on durability, so make sure your packaging meets International Safe Transit Association pre-shipment tests 1a and 3e.

In other words, your packaging should be able to easily withstand long-haul shipping (longer than 500 miles) without damage.

Your merchandise will undergo long journeys before it reaches a showroom, so it should be engineered to withstand forklift, pallet jack handling, and mechanical layer clamping. To accommodate changes in weather, packaging should easily withstand up to 90 percent humidity without losing structural integrity.

Products may be stored for as long as four weeks under extreme weight and temperature swings. A packaging engineer can test your products beforehand and ensure they are up to the task

Sample Packages

Display modules are a perfect choice for durability and convenience. A good display module will protect merchandise during shipping and transition seamlessly into a retail setting.

Master displays should be ready to hit the floor without requiring knives or any other tools for assembly. Modules have a 3-inch minimum front panel height although Costco recommends four inches. These requirements are waived if the product measures less than five inches in height.

Although the maximum weight is 40 pounds, Costco recommends modules not exceed 25 pounds to make transportation easier. Include center supporter dividers if your module features vertically unstable products like bulletin boards or picture frames. The optimum display module for Costco’s fixtures is 16 inches long, 13.3 inches wide, and 11.5 inches tall. It’s okay if your module doesn’t use these exact dimensions, but try to get it as close as possible.

Sample Packages

Costco prefers card-and-blister, stretch card, and box-and-blister packaging to clamshells.

Sustainability of your packaging is important because the store requires all packaging to be readily recyclable, compostable, or biodegradable by consumers. For example, rigid PVC is not usually recyclable in commercial facilities, so it is not accepted by Costco. Consider sourcing recycled materials like cardboard or plastic to reduce your waste footprint.

Conduct tests to prove your packaging will maintain structural integrity through the shipping process and after arriving at Costco. Suppliers are solely responsible for their own testing and packaging integrity. Costco recommends enlisting an experienced packaging engineer to test packaging strength.

Packaging must not only meet strength requirements but should be aesthetically pleasing to customers. Suppliers must ship full production samples to the store before they are considered. Plain packaging is extremely unlikely to get picked up in Costco’s competitive retail environment. A supplier who offers factory samples and understands the intricacies of Costco’s packaging guidelines is often helpful.

Sample Packages

Products spend most of their time on pallets while working their way through Costco’s supply chain, including when they are on the showroom floor. As a result, Costco has extremely high standards for its pallets.

Overland shipments must arrive palletized at Costco. For all North American locations, Costco only allows three pallet manufacturers: CHEP, PECO, and iGPS.

If you want to use a different, purpose built pallet, you need prior approval from Costco. Bear in mind that each item number requires its own approval, specific to its destination country and palletizing location. Approvals are only valid for one season, although long term approvals can last for up to one year.

Considerations for Home Depot

If you make construction or home improvement-related products, getting shelf space at Home Depot is a dream come true. Many vendors apply, which makes it competitive— getting and staying on Home Depot shelves requires a lot of work.

The payoff is huge, so make sure you’re ready for your pitch by understanding the following:

- Perhaps even more so than other retailers, Home Depot places a strong emphasis on sustainability and eco-friendly packaging. You should take this into account when preparing a product presentation, and ensure you can explain how your packaging aligns with the store’s values and goals.

- Home Depot also gives preference to diverse suppliers, including minority-owned, women-owned, veteran-owned, LGBTQ-owned, and disability-owned suppliers. If you fit into one of these groups, highlight it in your pitch.

- Home Depot values a transparent supply chain. If you have third-party verifications and supply chain documentation, present these during your pitch meeting.

Packaging Requirements

Home Depot has numerous technical packaging requirements, but they all focus on a series of central principles. All product packaging for Home Depot should:

- Enhance the customer’s shopping experience:

Make sure that packaging has a positive effect on the surrounding retail environment. - Provide protection for product integrity:

Consider durability at every step of your design process to ensure merchandise arrives in one piece. - Serve the customer from pre-purchase through product use and package disposal:

Take the entire life cycle of packaging into account. Is it recyclable and easily handleable by associates? - Minimize the material handling hazards associated with packaging for associates and

customers:

Avoid sharp edges and anything that could be potentially dangerous for shoppers or employees. - Contain sustainable materials:

Home Depot is much more likely to stock your product if it includes recycled or biodegradable materials.

In addition, packaging should always remain compliant with technical specifications. Familiarize yourself with these rules so you remain in good standing with Home Depot.

Sample Packages

Before committing to new packaging, consider the retailing information of your products.

For instance, all SKU numbers should be clearly visible and labels should include the manufacturer, packager, distributor name, and complete address.

If you include a warranty claim, include a contact number for customers. Products sold in Mexico must feature both English and Spanish where required by law. Per Canadian regulations, all information must be printed first in English, followed by French.

Consider rightsizing and loss prevention as you design brand packaging. Packaging should closely fit the product it protects to avoid wasted space. Expensive products may require Electronic Article Surveillance (EAS) security tags. If so, they should be easily incorporated into your packaging.

Sample Packages

When it comes to corrugated cardboard, which makes up the majority of product packaging, Home Depot has a series of strong preferences.

C-Flute corrugated is preferred for single wall boxes and B/C-Flute corrugated is ideal for double wall boxes, depending on weight, etc. Home Depot prefers RSC (Regular Slotted Container) boxes, although FOL (Full Overlap Slotted Containers) may be acceptable.

If products weigh more than 60 pounds, include access holes to accommodate a two-person lift. You always want to try to accommodate the needs of associates who will be handling your packaging in-store.

Sample Packages

As a rule of thumb, PDQ trays should easily withstand the weight of your products through the full life cycle of the packaging, from production to shipping and customer usage.

B-flute corrugated cardboard is the only acceptable material for PDQ trays. You should consider using a multi-wall board if you have a heavier product. To avoid accidents, make sure your burst strength is tested to a minimum of 200 psi.

When it comes to styles, Home Depot prefers Four-sided Rolled Edge PDQ trays and requires HSC covers with taped four edges to accommodate easy assembly.

Sample Packages

If you package your product with cut cases, your packaging should also function as a shelf display tray when it arrives at Home Depot. On the shelf, cut cases should hold products without any bulging or deformation.

As with other corrugated cardboard, Home Depot requires all cut cases to use B-flute structure and multi-wall board for heavier products. If you opt for a THD display, Home Depot prefers pull

Sample Packages

Generally speaking, there are two different types of quarter pallet (QP) displays: Standard QP displays and nested QP displays. Use standard QP displays if the empty area is 30 percent or less. If the empty area exceeds 30 percent , you should consider using a nested QP display.

Bear in mind that holiday displays may have different requirements. If you sell holiday-specific products, reach out to your contact at Home Depot and get more information.

Considerations for BJs

With locations exclusively along the East Coast and a handful of states in the Midwest, BJ’s is less ubiquitous than its competitors. Still, it pays to get your products on BJ’s shelves— generating over 16 billion dollars in revenue, it has a large and loyal customer base.

Stay compliant with these rules and regulations to find success with BJ's:

- BJ’s recently launched its Supply Chain Packaging Innovation Initiative, which plans to improve every aspect of the packaging supply chain and reduce costs by 2 percent every year. If you’re using innovative packaging that will help BJ’s cut costs, highlight this in your pitch meeting.

- The same initiative focuses on improving sustainability in the packaging supply chain. Mention any eco-friendly credentials in your pitch meeting. These can include using renewable energy, recycled materials, or co-packaging to conserve resources.

- BJ’s also values locally sourced products. Consider focusing on any benefits your company provides to the regional economy.

Sample Packages

Keep these BJ’s requirements in mind as you develop your packaging design process.

Display Tray Requirements

Unless you receive explicit permission from your BJ’s buyer, all items must include a display tray:

- Aisle tray dimensions: 19 1⁄2” x 23 1⁄2” x 10 1/4”

- End-cap dimensions: 23” x 15 3/8” x 10 1/4” and 20” L x 21” D x 11” H for a shelf.

Unlike other retailers, BJ’s does not allow tear front panels, inner wrapping, or bubble wrap. Opening instructions should be clearly visible so associates can prepare the tray for display. Check with your buyer for a special exception if your tray weighs more than 25 pounds.

BJ’s only accepts white corrugated cardboard for trays, and layer trays with egg-crate type partitions should not be more than 50 percent of the height of the product. If you plan to sell products in the freezer or dairy aisle, avoid using packaging with wax coating that is not recyclable. A good alternative is MRA (moisture resistant adhesive).

Your products are more likely to succeed at BJ’s if they include sustainable materials, including a high percentage of post-consumer content.

For display tray graphics, BJ’s prefers Preprint or Litho. All text and graphics should be approved by your buyer before you ship your merchandise. Any text should be clearly readable from six feet away. Display-ready pallets require specific approval from your buyer. Reach out to your contact at BJ’s to learn more.

Sample Packages

BJ’s puts particular emphasis on making products easily merchandisable from a 40-inch pallet display. If possible, products should also be compatible with a 48-inch pallet display. Try to imagine the customer’s experience as they reach for your product. Ensure that the product can be removed without damaging the tray or bumping into the horizontal beam above the display.

If you follow these guidelines, you should develop a constructive relationship with BJ’s, opening up new avenues for increased sales and volume.

Benefits of a Packaging Engineer

Pitching to big box retail stores isn’t always easy to navigate, and a packaging engineer could be the key to a successful pitch meeting. Packaging engineers offer:

- Technical expertise:

A packaging engineer has expertise in designing and testing packaging to ensure it meets the retailer’s requirements and can withstand the rigors of shipping, handling, and display. - Retailer compliance:

They can help ensure your packaging complies with each retailer’s regulations and packaging materials. - Cost efficiency:

A packaging engineer can help optimize the packaging design to reduce costs while maintaining quality and functionality. - Shelf impact:

They can design packaging that is visually appealing and increases the product’s shelf impact, helping it stand out among other products on the shelves. - Sustainability:

A packaging engineer can also help design eco-friendly packaging options to appeal to environmentally conscious customers and meet the retailer’s sustainability goals. - Samples and prototypes:

Working with the right packaging supplier will arm you with exactly what’s needed for your pitch. In this early stage, there’s no reason to invest in a full order of packaging, when what you need are factory samples that impress. A packaging engineer with design experience takes the guesswork out of creating samples that meet the requirements and wow each big box retailer.